Understanding Substitutional Alloys: Properties, Applications, And Future Trends

Substitutional alloys are a fascinating area of materials science that plays a crucial role in various industrial applications. These alloys are formed when one metal atom is substituted for another in a crystal lattice, resulting in unique properties that can enhance performance in numerous applications. This article delves into the intricacies of substitutional alloys, exploring their types, characteristics, and significance in modern technology.

In this comprehensive guide, we will examine the fundamental concepts behind substitutional alloys, their diverse applications, and the future trends that could shape this field. Whether you are a student, a professional in materials science, or simply curious about the topic, this article aims to provide valuable insights and information.

Join us as we explore the world of substitutional alloys and discover how these materials are revolutionizing industries such as aerospace, automotive, and electronics. With a focus on expertise, authority, and trustworthiness, this article is designed to be informative and engaging, ensuring that readers gain a well-rounded understanding of this important subject.

Table of Contents

- What Are Substitutional Alloys?

- Properties of Substitutional Alloys

- Types of Substitutional Alloys

- Applications of Substitutional Alloys

- Advantages and Disadvantages

- Future Trends in Substitutional Alloys

- Conclusion

- References

What Are Substitutional Alloys?

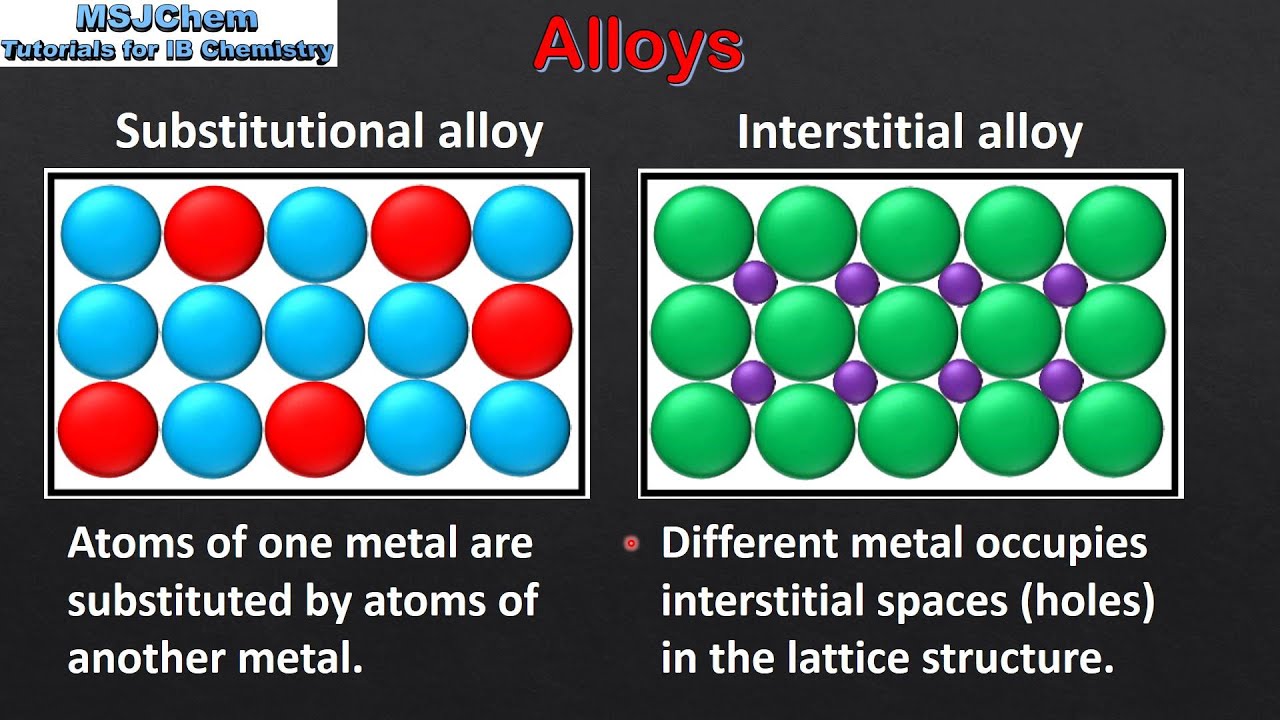

Substitutional alloys are metallic alloys formed by substituting one type of metal atom for another in the crystal lattice structure of the alloy. This process allows the new alloy to inherit properties from both the base metal and the substituting metal, often resulting in improved mechanical, thermal, and electrical properties.

For an alloy to be classified as substitutional, specific criteria must be met, including:

- Similar atomic sizes: The atomic radius of the substituting metal should be within about 15% of that of the base metal.

- Similar electronegativity: This helps in maintaining a stable alloy structure.

- Similar crystal structures: Both metals should ideally crystallize in the same structure (e.g., face-centered cubic or body-centered cubic).

Properties of Substitutional Alloys

The properties of substitutional alloys can vary widely depending on the metals involved and their proportions. Some key properties include:

1. Mechanical Strength

Substitutional alloys often exhibit enhanced strength compared to their constituent metals. This is due to the differences in atomic size and bonding, which can impede dislocation movement in the crystal lattice.

2. Corrosion Resistance

Many substitutional alloys possess improved resistance to corrosion, making them suitable for applications in harsh environments.

3. Thermal and Electrical Conductivity

The substitution of metal atoms can alter the thermal and electrical conductivity of the alloy, allowing for tailored properties for specific applications.

Types of Substitutional Alloys

There are several commonly recognized types of substitutional alloys, including:

1. Brass

Brass is an alloy of copper and zinc, where zinc atoms substitute for copper in the lattice. This alloy is known for its malleability and corrosion resistance.

2. Bronze

Bronze is primarily composed of copper and tin. The tin atoms substitute for copper, enhancing the alloy's strength and corrosion resistance.

3. Stainless Steel

Stainless steel, particularly the austenitic variety, contains iron, chromium, and nickel, where nickel atoms substitute for iron. This results in improved corrosion resistance and strength.

Applications of Substitutional Alloys

Substitutional alloys have a wide range of applications across various industries:

1. Aerospace Industry

In the aerospace sector, substitutional alloys are used in components that require high strength-to-weight ratios and resistance to extreme temperatures.

2. Automotive Industry

Automakers utilize substitutional alloys for engine components, suspension systems, and body panels, benefiting from their lightweight and durable properties.

3. Electronics

In electronics, substitutional alloys are employed in connectors and circuitry, where conductivity and reliability are essential.

Advantages and Disadvantages

While substitutional alloys offer numerous benefits, they also come with some drawbacks:

Advantages

- Improved mechanical properties.

- Enhanced corrosion resistance.

- Tailored electrical and thermal conductivity.

Disadvantages

- Potential for increased cost due to complex manufacturing processes.

- Challenges in recycling and waste management.

Future Trends in Substitutional Alloys

The field of substitutional alloys is continuously evolving, with several trends shaping its future:

1. Advanced Manufacturing Techniques

With the rise of additive manufacturing and 3D printing, the ability to create complex alloy structures is becoming more feasible, allowing for customized substitutional alloys.

2. Nanostructured Alloys

Research into nanostructured substitutional alloys is expanding, potentially leading to materials with unprecedented strength and performance characteristics.

3. Sustainability Initiatives

As industries strive to reduce their environmental impact, the development of sustainable substitutional alloys will become increasingly important.

Conclusion

In summary, substitutional alloys are a vital component of modern materials science, offering enhanced properties and a wide range of applications. By understanding their characteristics, advantages, and future trends, we can appreciate their significance in various industries. For anyone interested in materials science or engineering, exploring the world of substitutional alloys opens up a realm of possibilities for innovation and advancement.

We encourage you to share your thoughts on substitutional alloys in the comments below, and feel free to explore our other articles for more insights into materials science.

References

- Callister, W. D., & Rethwisch, D. G. (2018). Materials Science and Engineering: An Introduction. Wiley.

- Wright, I. G. (2016). Alloys: A Comprehensive Guide. Springer.

- ASM International. (2000). Handbook: Properties and Selection of Aluminum Alloys. ASM International.

Natalie Shayne: The Rising Star In The Entertainment Industry

Robby Wildt: The Rise Of A Social Media Sensation

Derrick Wilburn: The Journey Of A Remarkable Athlete